Differences and precautions in processing copper busbars vs. aluminum busbars

When punching, cutting, and bending copper and aluminum busbars, to avoid obvious bright bands/shear bands or even burrs on the processed cross-section, it is recommended to establish two independent parameter libraries (“Copper-Lib” and “Aluminum-Lib”) in the CNC system of the busbar machine, and to distinguish between copper busbar-specific molds and aluminum busbar-specific molds for the…

When high and low voltage switchgear manufacturers or electrical panel factories use busbar machine (related: Apa itu mesin busbar?) to process copper and aluminum busbars, if the technical engineers do not understand the physical properties (hardness, ductility, resilience) of the two metal materials, the finished product will be uncontrollable when punching, cutting and bending copper and aluminum busbars. This will result in obvious bright zone/shear zone, or even burrs, which will affect the quality and service life of the switchgear or electrical panel.

Copper busbars and aluminum busbars have significantly different physical properties, resulting in drastically different processing parameters and precautions. The following is a detailed analysis of the differences and specific precautions for machining these two materials in busbar machine processing:

Physical properties of copper busbars and aluminum busbars

| Fitur | Copper busbar | Aluminum busbar | Processing impact |

|---|---|---|---|

| Hardness | Higher | Lower (Softer) | Copper requires greater shearing and punching pressure; aluminum tends to stick to the tool. |

| Ductility | Excellent | Good, but Brittle and easily broken | Copper can be bent with a small radius angle; aluminum is prone to cracking under small radius angles. |

| Rebound Rate | Smaller, more stable | Large and unstable | The bending angle compensation for aluminum needs to be set to a larger value. |

| Surface | Average scratch resistance | Very easy to scratch | Aluminum busbars require extra care during feeding and processing. |

When punching copper busbars, the cut surface is usually clean with few burrs. However, due to the hardness of copper, the punching die head wears relatively quickly, requiring regular checks of the punch’s sharpness.

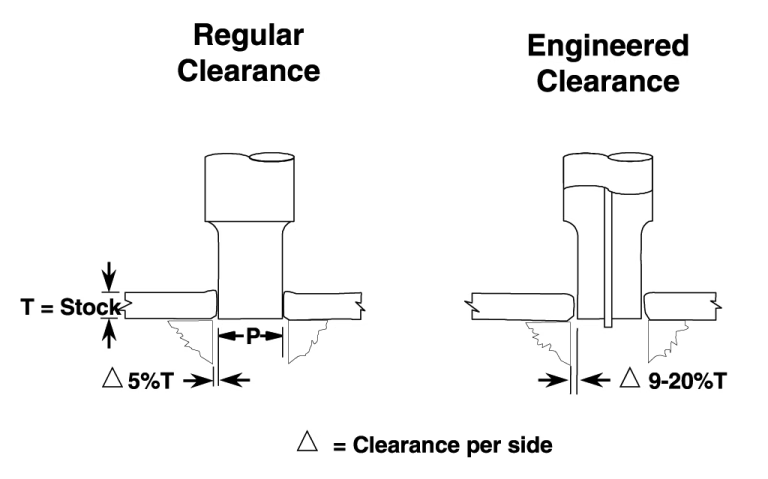

When punching aluminum busbars, the soft and sticky nature of aluminum makes it prone to **Galling**, where aluminum shavings adhere to the punch or die. Therefore, the die must be cleaned more frequently to prevent shavings buildup that could cause punching deformation or die jamming. For aluminum busbars, the die clearance can be appropriately reduced to ensure a smooth hole wall.

Differences and precautions in punching unit processing

When punching copper busbars, the cut surface is usually clean with few burrs. However, due to the hardness of copper, the punching die head wears relatively quickly, requiring regular checks of the punch’s sharpness.

When punching aluminum busbars, the soft and sticky nature of aluminum makes it prone to **Galling**, where aluminum shavings adhere to the punch or die. Therefore, the die must be cleaned more frequently to prevent shavings buildup that could cause punching deformation or die jamming. For aluminum busbars, the die clearance can be appropriately reduced to ensure a smooth hole wall.

Kiat: Requirements for die clearance when punching copper and aluminum busbars.

Differences and precautions in cutting unit processing

Copper busbars have high shear resistance and typically have a bright cross-section. However, one crucial point must be noted: ensure the shear blade is sharp. If the blade is dull, the copper busbar cross-section is prone to chipped corners or severe burrs.

Aluminum busbars, on the other hand, have low shear resistance but are easily deformed (flattened). During shearing, the pressure of the clamping foot (pressing device) must be moderate. Excessive pressure may leave indentations on the aluminum busbar surface, while insufficient pressure will result in a non-perpendicular cross-section.

Differences and Precautions in Bending Unit Processing – The Most Critical Step

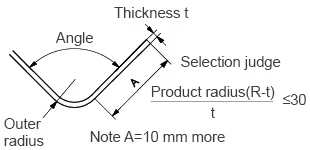

This is the process with the biggest difference between the two, mainly in the **bending radius (R angle) and springback compensation**.

Copper busbars have good ductility and can usually use smaller R angle dies (e.g., R = busbar thickness), making them less prone to cracking. Their springback angle is smaller (usually around 3°-5°), making CNC control easier.

Aluminum busbars (especially hard aluminum) are extremely prone to cracking when stretched on the outside. This requires that **larger bending R angle dies must be used when processing aluminum busbars**, and **it is generally recommended that the R angle be ≥ 1.5 to 2 times the aluminum busbar thickness**. The springback rate of aluminum is also usually greater than that of copper (depending on the aluminum grade), and there is significant batch-to-batch variation. If the target angle is 90°, copper may only need to be bent to 92°, while aluminum may need to be bent to 95° or even more to spring back to 90°. It is recommended to set up a separate material library parameter for aluminum busbars in the CNC system.

Operation and maintenance precautions

- **Mold Protection (Recommended)**

- Although copper and aluminum can use the same set of molds, to prevent **electrochemical corrosion** (copper-aluminum contact accelerates corrosion in humid environments), it is recommended to use separate molds for copper and aluminum whenever possible. If mixing is unavoidable, thoroughly clean any metal shavings from the molds before switching materials.

- **Surface Protection:**

- Aluminum busbars are very easily scratched. When dragging aluminum busbars for positioning, avoid dragging them hard on the worktable. It is recommended to apply anti-abrasion rubber pads to the worktable of the busbar machine or use an auxiliary bracket with rollers.

- **Lubrication:**

- When punching holes in aluminum busbars, apply a small amount of special lubricating oil or alcohol to the punch to reduce adhesion and improve demolding smoothness.

Summary and Recommendations

If you are conducting mass production, it is recommended to establish two independent parameter libraries (“Copper-Lib” and “Aluminum-Lib”) in the CNC system of the busbar machine, and to distinguish between copper busbar-specific dies and aluminum busbar-specific dies for the punching unit. It is crucial to record the different bending elastic coefficients and die radius selections for both. This way, when switching materials, you can simply call up the relevant parameters with one click, eliminating the need for repeated die trials.

Artikel yang direkomendasikan

Pameran Impor dan Ekspor Tiongkok Merekomendasikan MESIN BUSBAR SUNSHINE®

Hubungi kamiDapatkan Penawaran Harga Mesin Busbar Terbaik dari SunShine® di Tiongkok

Tinjau kebutuhan Anda dengan cepat dan berikan solusi teknis profesional secara efisien! Kami mendengarkan dan peduli dengan kebutuhan Anda. Orang-orang kami akan menghubungi Anda melalui email dan panggilan telepon dalam waktu 24 jam.

Di mana bisa membeli mesin busbar yang berkualitas dan dapat diandalkan?

Kami adalah produsen dan pabrik mesin busbar China. Silakan hubungi manajer penjualan kami Lisa (Surel: lisa@busbarmachine.co) dan menyediakan gambar busbar atau contoh produk. Kami akan mengevaluasi dan membuat produk atau produk yang direkomendasikan terbaik untuk Anda. Kustomisasi mesin busbar (fungsi atau PLC), dan penawaran teknis lengkap disediakan.

Dengan anggaran terbatas, model mesin busbar mana yang harus dibeli?

SUNSHINE memiliki mesin busbar ekonomis dan mesin busbar CNC otomatis berkinerja tinggi, dan dapat menyesuaikan rencana penawaran teknis sesuai dengan lokasi produksi pelanggan, persyaratan pemrosesan busbar, dan anggaran modal. Silakan hubungi manajer penjualan profesional kami Lisa (Surel: lisa@busbarmachine.co) untuk dukungan teknis dan layanan penawaran harga.

Selain mesin busbar, apakah Anda menyediakan cetakan busbar?

Kami biasanya memberikan beberapa cetakan busbar, termasuk pembengkokan, pemotongan, pelubangan, dan pengembosan, dll. Jika Anda memiliki persyaratan cetakan busbar khusus, kami dapat menyesuaikannya untuk Anda, dengan harga mulai dari US$40 hingga US$100.

Berapa tegangan mesinnya?

Tegangan standarnya adalah 3 fase, 220 V, 60 Hz. Tegangan dapat disesuaikan sesuai kebutuhan pelanggan.

Berapa lama waktu tunggunya?

Hal ini bergantung pada ketersediaan inventaris dan kompleksitas mesin busbar. Biasanya, diperlukan waktu hingga 3 hari jika kami memiliki stok busbar yang sesuai, dan untuk mesin busbar yang perlu diproduksi dari awal hingga akhir, kami biasanya memerlukan waktu sekitar 7 hingga 15 hari. Untuk mesin yang rumit atau jalur produksi busbar, kami memerlukan waktu sekitar 20 hingga 30 hari.

Apa kebijakan garansi Anda?

Kami menyediakan garansi 12 bulanan jika penggunaan benar. Akan menyediakan bantuan jarak jauh dan mengirimkan suku cadang pengganti gratis selama masa garansi.

Apa syarat pembayaran Anda?

Syarat pembayaran kami adalah pembayaran di muka 30% dan pembayaran saldo 70% sebelum pengiriman.

Bisakah Anda mengirim teknisi ke luar negeri untuk melakukan layanan instalasi, pelatihan, atau pengujian di tempat?

Semua mesin akan diuji dan di-debug sebelum dikirim. Pada prinsipnya, kami hanya menyediakan layanan debugging jarak jauh dan bantuan teknis jarak jauh. Jika itu adalah jalur produksi busbar, kami akan menempatkan teknisi di lokasi untuk melakukan servis di lokasi.

Bisakah kami mengunjungi pabrik Anda atau melakukan inspeksi di tempat?

Kami sangat menyambut pelanggan untuk mengunjungi dan memeriksa pabrik. Silakan hubungi manajer penjualan kami Lisa (Surel: lisa@busbarmachine.co) dan beri tahu kami jadwal Anda. Kami akan mengirimkan surat undangan bisnis resmi kepada Anda.

Bisakah saya menjadi distributor pabrik Anda di negara kami?

Kami sangat menyambut Anda untuk mendaftar menjadi distributor mesin busbar kami dan bersama-sama mengembangkan pasar luar negeri. Kami akan memberikan komisi penjualan yang besar dan insentif tunai tambahan. Untuk konten dan metode kerja sama tertentu, silakan hubungi CEO kami Robin (Surel: ceo@busbarmachine.co).